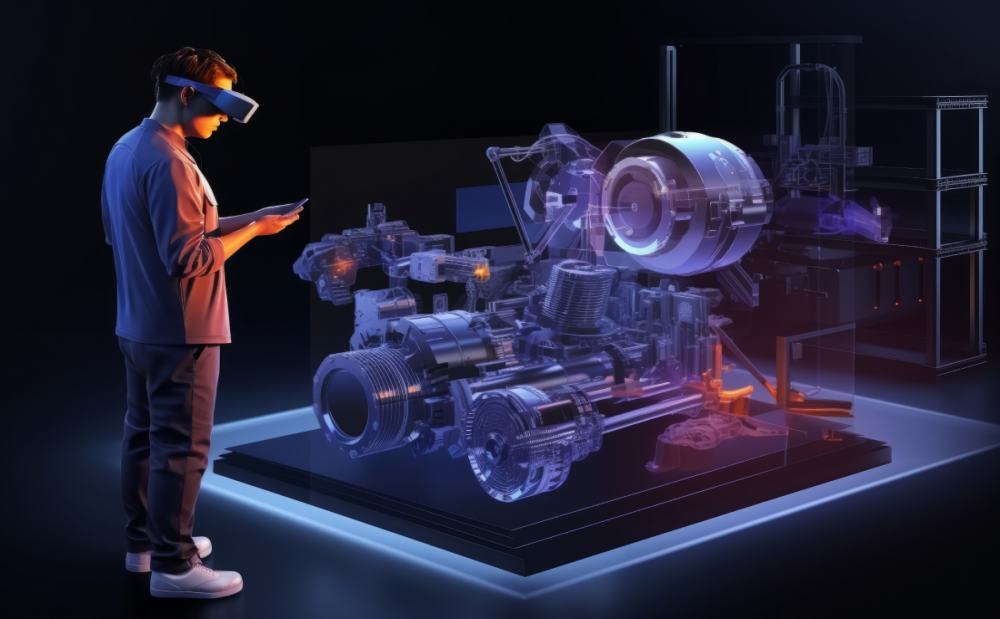

Training and Simulation

- Realistic Training Environments: VR creates lifelike training scenarios, allowing employees to practice complex tasks in a safe and controlled environment.

- Reduced Training Costs: Simulating real-world manufacturing processes in VR reduces the need for physical materials and equipment, cutting down training costs.

- Enhanced Skill Retention: Interactive VR training improves knowledge retention and skill acquisition compared to traditional methods.